A new report by WSJ sheds light on Apple Silicon, the story behind how it was planned, and what challenges the company faced internally. The report also includes an interview with Johny Srouji, senior vice president of Hardware Technologies at Apple.

The introduction of the M1 chip played a crucial role in boosting Mac sales. From $28.6 billion and below in 2022 and in previous years, sales of Macs jumped to $35.2 billion in 2021. Thanks to the M1 chip family, Apple ranks as the 12th largest chip company in the world by revenue, as per an estimate by Wayne Lam, CSS Insight analyst.

The story of Apple Silicon

Perhaps one of the biggest reasons why Apple kickstarted its Apple Silicon migration can be attributed to Intel’s overheating chips. As WSJ notes, former Intel engineer François Piednoëls said in 2020 that Apple folks were number one in filing issue reports with Intel’s architecture which meant that the chips had to be held back to prevent overheating in Macs, which impacted performance and battery.

“It was abnormally bad. Our buddies at Apple became the number one filer of problems in the architecture. And that went really, really bad. When your customer starts finding almost as many bugs as you found yourself, you’re not leading into the right place.”

To deliver on its silicon migration, Apple had to not only work on the hardware architecture of its chips, but the company’s engineers also had to rewrite its software to ensure that it would work well on both Intel and M1 chips. This was not a simple process and something that rarely any other company has done before, let alone multiple times like Apple.

Apple has experience with migrating chip architectures before, especially in 2006 when it moved from PowerPC to Intel, due to issues with performance and efficiency. These are the same reasons that compelled Apple to ditch Intel.

There was a strong debate internally at Apple especially due to the risk that was associated with the migration. Apple’s migration from PowerPC to Intel had several internal challenges, however, in the end, the company delivered successfully back then as it has delivered now.

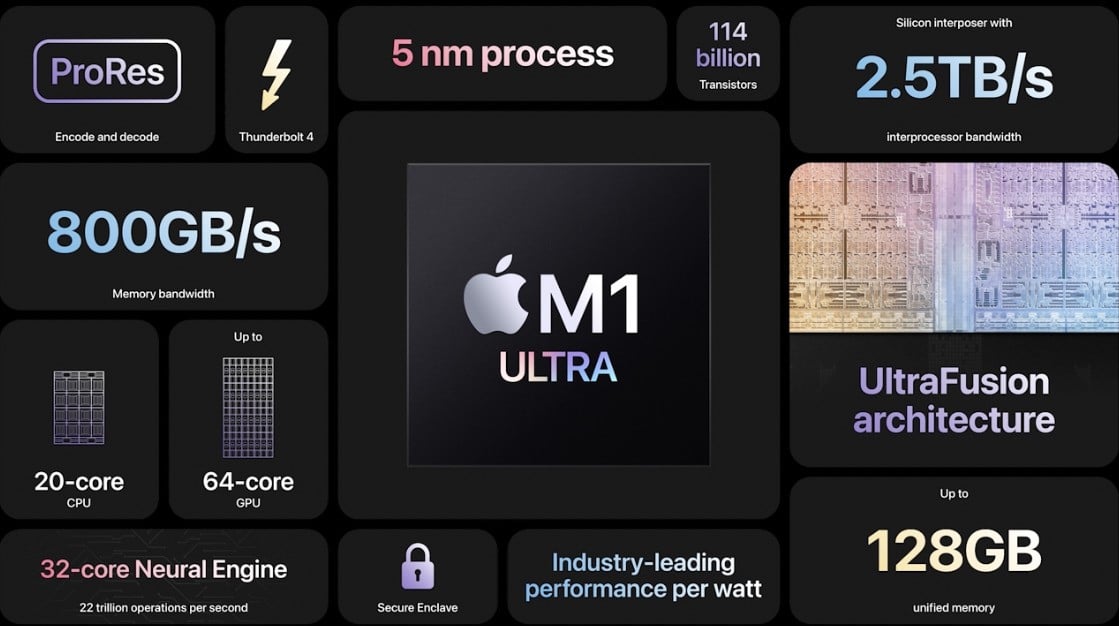

The teams at Apple worked on efficiency and performance while making sure that the chip scales from devices like the $999 MacBook Air as well as workstation level devices like Mac Studio. This also meant that the company would have to create a roadmap to ensure that Apple Silicon can continue to be future-proof, depending on where technology would be headed.

Apple decided to ensure that its iPhone chips strategy would be applied to Macs. This would include the development of a translation layer, that could support existing Intel apps on M1 chips, which are based on the Arm architecture. Apple also spent billions in R&D over the years, including the acquisition of companies like PA Semiconductor to aid in these efforts.

One of the challenges Apple faced was the pandemic, which caused issues with delivering the M1 chips. Regarding working on Apple Silicon M1 chips during the COVID-19 pandemic, Johny Srouji, Apple’s senior vice president of hardware technologies, told WSJ:

“What I learned in life: You think through all of the things you can control and then you have to be flexible and adaptive and strong enough to navigate when things don’t go to plan. Covid was one for example.”

To counter the impact on productivity during the pandemic, Apple developed a new testing process that would allow engineers to test and inspect chips remotely in the company’s labs through the use of cameras while ensuring complete security. Johny Srouji’s team was spread around the world, which also helped them easily maneuver through the pandemic through video calls and different time zones.

Apple Silicon passed final testing and validation in 2020 and production began by TSMC on the 5nm node. The rest, as they say, is history. The M1 chip family is now used in MacBook Air, Mac mini, 24-inch iMac, 13-inch MacBook Pro, 14-inch MacBook Pro, 16-inch MacBook Pro, and Mac Studio. It has even found its place on the iPad Pro and even the iPad Air, which is the cheapest device that ships with an M1 chip at $599.

The Mac Pro is yet to be upgraded to Apple Silicon, and in typical Apple fashion, Srouji declined to comment on the company’s future plans.