The US Patent and Trademark Office has granted Apple multiple patents related to “Force or 3-D Touch” technology for Apple Watch, MacBook, and even iPhone.

In 2014, Apple introduced the “Force Touch” technology in the Apple Watch. Using pressure sensors, the touch-screen technology enabled the device to distinguish between different levels of force being applied to the touchscreen and perform different functions like displaying content on the screen and accessing shortcuts. Force Touch tech was later incorporated in MacBook models and Magic Trackpad 2, and for iPhone, it was called 3-D Touch. However, Apple discontinued the tech from all products and replaced it with Haptic Touch, only the screen distinguishes between a tap and a long press.

Apple to use new “microelectromechanical fluid pressure sensors” to re-introduce Force Touch in future products

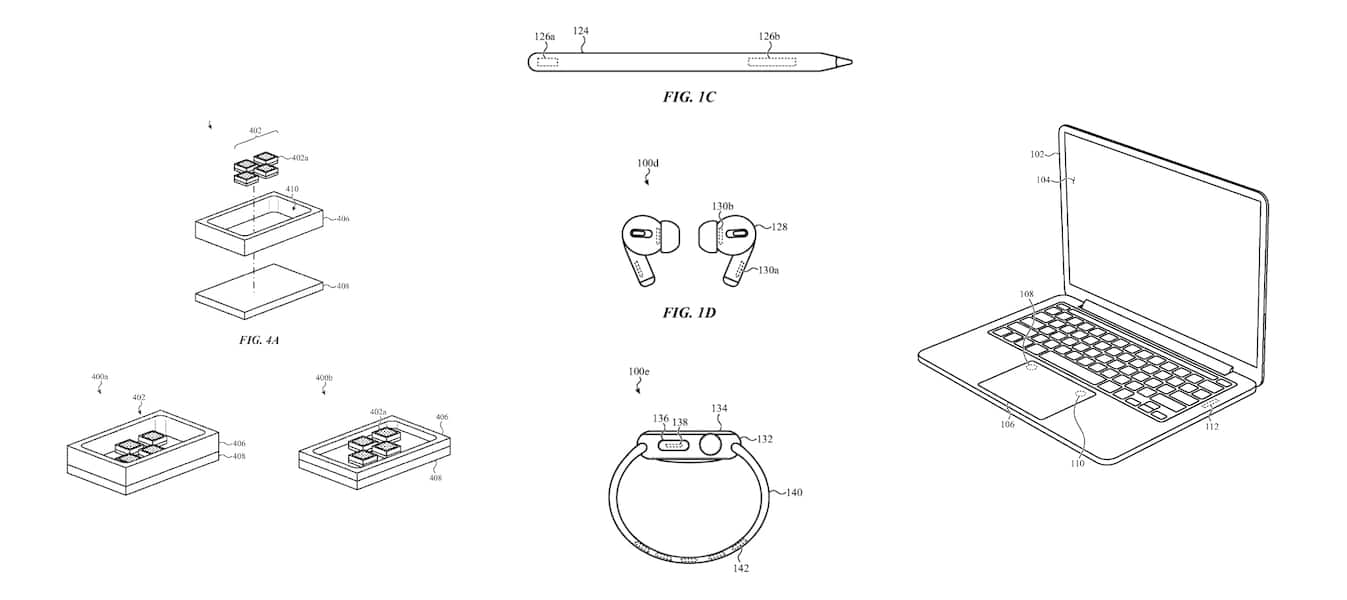

All six of Apple’s patents detail the use of new force-pressure sensors in future Apple Watch, AirPods, MacBook, and even iPhone for different purposes like wearable applanation tonometer, sensing structure for pulse-wave velocity, determining pulse transit time of wearer, sensing pressure in portable electronic devices, sensing pressure and barometric, and introducing an interface pressure sensor system.

All the filings explain that conventional force sensors occupy a lot of space in the housing of an electronic device which does not make them suitable to be used in smaller portable electronic devices such as AirPods. Furthermore, as they are delicate, they lack durability and are expensive. Therefore, they are not suitable for small form devices and wearables like AirPods, Apple Watch, and other products.

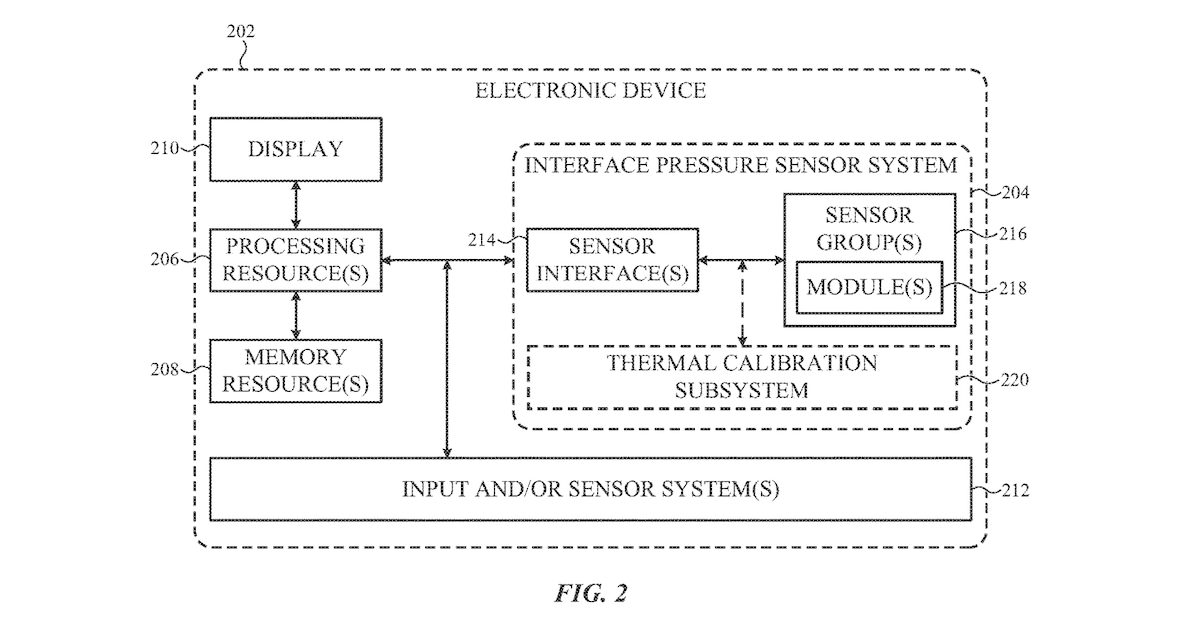

An electronic device can include a force sensor. Conventional force sensors are typically implemented with compressible capacitive plates, piezoelectric materials, piezoresistive materials, strain-sensitive materials, and the like. However, in part as a direct result of these architectures and materials, conventional force sensors reserve substantial volume and/or area with an electronic device housing, and may not be readily or efficiently incorporated into portable or low-profile applications. In addition, conventional force sensors typically have structurally-limited and/or nonlinear force sensitivity that render such sensors unable to accurately or precisely detect small or gradual changes in force.

Further still, many conventional high precision and high accuracy force sensors (which may be used in medical, scientific, or industrial applications) are typically delicate and/or expensive, requiring specialized training to install, service, and operate.

Thus, the company proposes the use of a new “microelectromechanical fluid pressure sensor” in portable electronic devices to reintroduce Force Touch technology.

Embodiments described herein take the form of an interface pressure sensor system for an electronic device. The interface pressure sensor system defines a sensing surface configured to receive a normal force. The sensing surface forms a portion of a potting, infill, or encapsulation material disposed over, and enclosing, a microelectromechanical fluid pressure sensor. As a result of this construction, when the sensing surface receives a force, the encapsulation material transits that force, or at least a portion thereof, to a microelectromechanical force or pressure sensitive structure that deforms in response.

A property of an electrical circuit conductively coupled to the microelectromechanical sensor can be converted into a force applied to the sensing surface. A surface area of the sensing surface can also be leveraged to determine a pressure applied to the interface pressure sensor system. In another phrasing, a force detected by the interface pressure sensor system can be divided by the surface area of the sensor to obtain a pressure measurement.

via Patently Apple

Read More: